When performing inspections of cold-formed steel framing, one of the most obvious aspects to check is the material thickness (mils or gauge). Some experienced tradespeople can tell the difference between standard thicknesses by feel alone, but thankfully there are many ways to easily identify CFS thickness — including by color.

In this guide, learn how read the printed code, which is stamped by the manufacturer on each stud, and how you can identify thickness just by the color painted on the end of steel studs and tracks. We’ll also talk about what to do if no identifying marks are visible — plus, we’ll provide you with the most common cold-formed steel metal framing (CFMF) sizes and shapes.

How to Read the Printed Code

Color Guide

Online Metal Thickness Gauges

The Most Common CFMF Sizes & Shapes

Before you get started, here’s a link to our most popular presentation on bidding projects and identifying costly details. Click here to watch.

How to Read the Printed Code

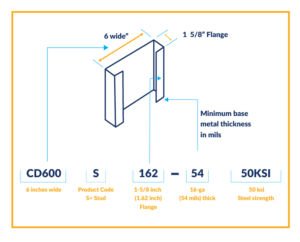

Metal stud manufacturers are required to stamp the stud size and gauge on each product. For instance, ClarkDietrich labels 6-inch, 16-gauge studs with CD600S162-54 50 KSI. This tells you the stud is 6 inches wide with a 1-5/8 inch (1.62 inch) flange and is 16-ga (54 mils) thick. Finally, it shows the steel strength to be 50 ksi. However, some studs are cut or positioned in a fashion that makes reading these labels difficult. In those cases, inspectors can look for paint markings.

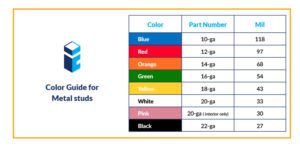

Before leaving the factory, ends of steel studs and tracks are painted with color markings to indicate thicknesses. For example, green paint indicates 16-ga (54 mils) and yellow paint indicates 18-ga (43 mils).

Color Guide:

- Blue – 118 mils (10-ga)

- Red – 97 mils (12-ga)

- Orange – 68 mils (14-ga)

- Green – 54 mils (16-ga)

- Yellow – 43 mils (18-ga)

- White – 33 mils (20-ga)

- Pink – 30 mils (20-ga; interior only)

- Black – 27 mils (22-ga)

If no identifying marks are visible, one can use a micrometer to measure the material thickness. We recommend using a C-shaped outside micrometer.

Inside micrometers are hard to use with the rounded, sheared edges of cold-formed steel, making reliable measurements difficult. Take multiple measurements to gain confidence that you have accurately determined the thickness.

Online Metal Thickness Gauges

There are several metal thickness gauges available online. Unfortunately, most of these gauges are for sheet metal thicknesses and not for cold-formed structural steel. Still, they can get you close enough to allow you to make a good judgment about the thickness. It is best to make measurements at the stud knockouts and away from rolled edges.

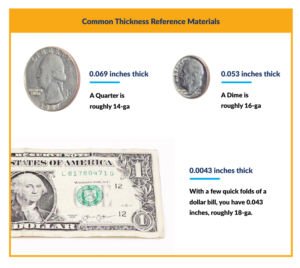

When all else fails, remember these common thickness reference materials that you might have in your pocket:

- A quarter is 0.069 inches thick, roughly 14-ga

- A dime is 0.053 inches thick, roughly 16-ga

- A dollar bill is 0.0043 inches thick. With a few quick folds, you have 0.043 inches, roughly 18-ga

The Most Common CFMF Sizes & Shapes

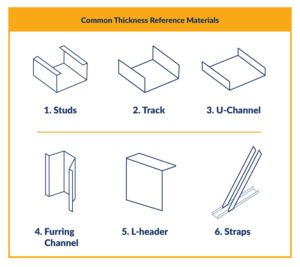

1. Studs

A stud refers to cold-formed steel that has been formed into a C-shape with a lip return. These are typically used as a vertical element in the framing of a wall. The most common sizes are6” and a 35/8” wide studs. Widths are available up to 16-inches.

2. Track

A track section will often cap the bottom and top of a steel stud wall. These products are U-shaped and do not have a lip return to allow the stud to seat inside the track. The most common sizes are the same as studs.

3. U-channel

This is a smaller U-shaped product that goes through the web knockout of each stud for bracing or will often be used to support ceiling framing with hanger wire. They are sometimes referred as cold-rolled channel or CRC. The most common sizes are 3/4”, 1-1/2” and 2”.

4. Furring channel

This refers to a “hat-channel” type of CFS that is often applied to the face of a wall or bottom of a ceiling in order to provide a wedge or spacing element (otherwise known as furring) to the sheathing. The most common furring channel sizes are 7/8” and 1-1/2”.

5. L-header

This piece of CFS is a large angle, or L-shaped, and is positioned on top of the wall top track to act as a simple header. They span across openings to help transfer the load over a door or window onto jamb studs. L-headers are available in a wide variety of dimensions. They are typically custom bent.

6. Straps

Straps are 2” to 12”-wide thin sheets of steel used for tension loads. They will most often be found in wall bracing or shear walls.

If you have questions about cold-formed steel services, or you’re looking for a quote for your next project, please contact us today. We look forward to answering your questions and learning how we can help.