The Project

Interior Building Contractors (IBC) turned to Iron Engineering to help with the construction of KindCare Assisted Living, a 60,800-square foot assisted living facility in Bristol, Conn. The five-story structure, which includes 89 assisted living beds and 29 memory care beds, consists of load bearing cold-formed steel (CFS) framing, a COMSLAB® flooring system, a reinforced concrete foundation, and cold-formed steel roof trusses with metal roof deck.

The Challenges

The general contractor, IBC, was relatively new to panelized construction, which is the process of pre-assembling wall sections in a factory, shipping those panels to the construction site, and erecting the panels into place with a crane or lift at the project location.

A significant challenge was ensuring accuracy with the wall framing due to tight constraints of the exterior walls, caused by the placement of the heating and ventilation systems underneath the windows.

Contractors also had to contend with large first-floor windows. Since the exterior walls were load bearing, and the upper floors featured small windows, there were four stories of jamb loading bearing down in the middle of the window opening span.

The Solutions

Due to Iron Engineering’s extensive experience with panelized construction and designing with cold-formed steel, as well its past relationship with IBC on several successful load bearing projects, Iron Engineering was the clear choice to overcome this project’s challenges. Iron Engineering prepared a set of CFS shop drawings, panel erection drawings, and panel ticket drawings for the entire building.

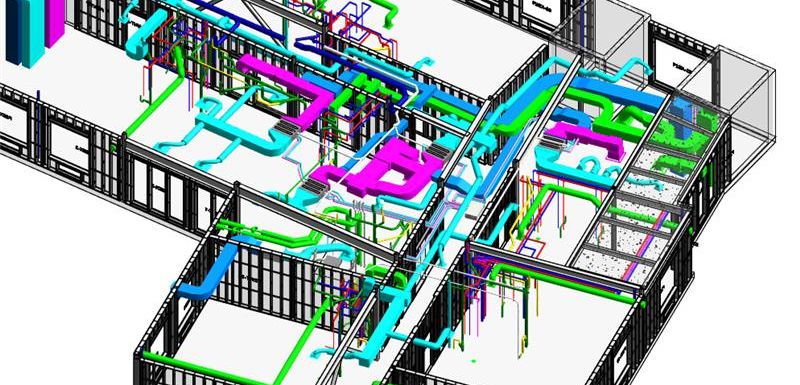

Iron Engineering coordinated with the mechanical systems on the project. The structural drawings were first completed with a 2D computer-aided design (CAD) software; Iron Engineering then created a model of the drawings in Autodesk’s BIM Revit® using MWF add-on software, a framing solution from StructSoft Solutions. Iron Engineering brought the mechanical engineering model into Revit so that they could make changes to the CFS framing in order to accommodate the mechanical systems. If the systems could not be changed, Iron Engineering requested the mechanical systems be modified to accommodate the CFS framing. The team worked together to achieve this successfully.

When it came to the challenge of the large, first-floor windows, Iron Engineering recommended using structural steel and splitting the project into two unique windows joined together with a larger center jamb. The framing details on this modification, however, were extremely complicated, so Iron Engineering included a QR code on the plans that linked to an audio recording with specific instructions. This was a well-received step that helped ensure everyone involved received the right details.

The KindCare project is slated for completion in spring 2023.