Metal stud manufacturers are required to stamp the stud size and gauge on each product. For instance, ClarkDietrich labels 6-inch, 16-gauge studs with CD600S162-54 50 KSI. This tells you the stud is 6 inches wide with a 1-5/8 inch (1.62 inch) flange and is 16-ga (54 mils) thick. Finally, it shows the steel strength to be 50 ksi.

Since the materials come off rollers being fed by large coils of steel, the limiting factor on stud/track lengths is the size of the rolling facility and the ability to ship it to the job site.

Pay attention to stud heights as a small difference in height, such as 3-feet, can change the required gauge to increase two increments. Strict deflection limitations can also drive costs. Consider the geographic area (in terms of high wind speeds near the coast). If you aren’t sure which sizes you need, it’s best to consult a cold-formed steel engineer.

ClarkDietrich’s plant in Bristol, Conn. can roll a stud/joist well over 100 feet long. Shipping is the limiting factor. For practicality sake, we recommend maximum stud lengths around 40 feet depending upon the size. Smaller and thinner studs are very difficult to work with as they get longer. It’s best to consult your specialty engineer to make the appropriate decision for your project.

Typical Metal Stud Sizes

Interior Framing and Metal Stud Sizes

| Stud | Member Depth (in) | Flange Width (in) | Material Thickness (mils) |

| 1-5/8 | 1-1/4 | 15, 18, 19, 30, 33 | |

| 2-1/2 | 1-1/4 | 15, 18, 19, 30, 33 | |

| 3-5/8 | 1-1/4 | 15, 18, 19, 30, 33 | |

| 4 | 1-1/4 | 15, 18, 19, 30, 33 | |

| 6 | 1-1/4 | 15, 18, 19, 30, 33 | |

| Track | Member Depth | Flange Width | Material Thickness (GA) |

| 1-5/8 | 1-1/4, 2, 2-1/2 | 15, 18, 19, 30, 33 | |

| 2-1/2 | 1-1/4, 2, 2-1/2 | 15, 18, 19, 30, 33 | |

| 3-5/8 | 1-1/4, 2, 2-1/2 | 15, 18, 19, 30, 33 | |

| 4 | 1-1/4, 2, 2-1/2 | 15, 18, 19, 30, 33 | |

| 6 | 1-1/4, 2, 2-1/2 | 15, 18, 19, 30, 33 |

Exterior Structural Track and Metal Stud Sizes

| Structural Steel Stud | Member Depth | Flange Width | Material Thickness (GA) |

| 1-5/8 | 1-3/8, 1-5/8 | 20-16 | |

| 2-1/2 | 1-3/8, 1-5/8, 2, 2-1/2 | 20-14 | |

| 3-1/2 | 1-3/8, 1-5/8, 2, 2-1/2 | 20-14 | |

| 3-5/8 | 1-3/8, 1-5/8, 2, 2-1/2 | 20-12 | |

| 4 | 1-3/8, 1-5/8, 2, 2-1/2 | 20-12 | |

| 5 | 1-3/8, 1-5/8, 2, 2-1/2 | 20-12 | |

| 6 | 1-3/8, 1-5/8, 2, 2-1/2, 3 | 20-12 | |

| 8 | 1-3/8, 1-5/8, 2, 2-1/2, 3 | 20-12 | |

| 10 | 1-5/8, 2, 2-1/2, 3, 3-1/2 | 18-10 | |

| 12 | 1-5/8, 2, 2-1/2, 3, 3-1/2 | 16-10 | |

| 14 | 1-5/8, 2, 2-1/2, 3, 3-1/2 | 16-10 | |

| Structural Steel Track | Member Depth | Flange Width | Material Thickness (GA) |

| 1-5/8 | 1-1/4, 1-1/2, 2 | 20-16 | |

| 2-1/2 | 1-1/4, 1-1/2, 2, 3 | 20-14 | |

| 3-1/2 | 1-1/4, 1-1/2, 2, 3 | 20-14 | |

| 3-5/8 | 1-1/4, 1-1/2, 2, 3 | 20-12 | |

| 4 | 1-1/4, 1-1/2, 2, 3 | 20-12 | |

| 5-1/2 | 1-1/4, 1-1/2, 2, 3 | 20-12 | |

| 6 | 1-1/4, 1-1/2, 2, 3 | 20-12 | |

| 8 | 1-1/4, 1-1/2, 2, 3 | 20-12 | |

| 10 | 1-1/4, 1-1/2, 2, 3 | 18-10 | |

| 12 | 1-1/4, 1-1/2, 2, 3 | 16-10 | |

| 14 | 1-1/4, 1-1/2, 2, 3 | 16-10 |

Slotted Track

| Structural | Member Depth | Flange Width | Material Thickness (GA) |

| 2-1/2, 3-5/5, 4, 5-1/2, 6, 8 | 2-1/2 | 20-14 | |

| 2-1/2, 3-5/5, 4, 6, 8 | 3 | 20-14 | |

| Non-Structural | Member Depth | Flange Width | Material Thickness (mils) |

| 2-1/2, 3-5/5, 4, 6, 8 | 2-1/2 | 30-33 |

Accessories

| Product | Member Depth | Material Thickness (mils) |

| Furring Channel | 7/8″ | 18, 30, 43, 54 |

| Furring Channel | 1-1/2″ | 18, 30, 43, 54 |

| Z-Furring | 1″ | 18 & 30 |

| Z-Furring | 1-1/2″ | 18 & 30 |

| Z-Furring | 2″ | 18 & 30 |

| Z-Furring | 2-1/2″ | 18 & 30 |

| Z-Furring | 3″ | 18 & 30 |

| Z-Furring | 1-1/2″ | 18 & 30 |

| Z-Furring | 2″ | 18 & 30 |

| Z-Furring | 2-1/2″ | 18 & 30 |

| Z-Furring | 3″ | 18 & 30 |

| Z-Girt | 1-1/2″ | 33, 43, 54 |

| Z-Girt | 2″ | 33, 43, 54 |

| Z-Girt | 2-1/2″ | 33, 43, 54 |

| Z-Girt | 3″ | 33, 43, 54 |

| Z-Girt | 3-1/2″ | 33, 43, 54 |

| Z-Girt | 4″ | 33, 43, 54 |

| Spazzer Bar | 7/8″x7/8 | 33 |

| Spazzer Bar | 1-1/4″x1-1/4″ | 43 |

| Spazzer Bar | 1-1/4″x1-1/4″ | 54 |

| U-Channel | 3/4″ | 54 |

| U-Channel | 1-1/2″ | 54 |

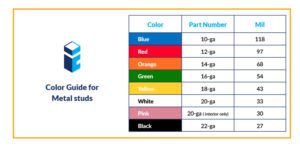

Here is an explanation of stud sizes in reference to thickness:

When to Use Certain Metal Stud Sizes

In general, the capacity of a stud depends on many variables — stud size, height, gauge, bracing condition, and lateral load.

Heavy-duty projects that require stability and a strong foundation typically need thicker metal studs.

In some cases, unusual stud sizes — or metal studs that match standard wood sizes — are requested for a project. If you’re looking for something specific, please contact us today.

If you’d like additional information on how to identify cold-formed steel material thicknesses in the field, read our blog post here.