Cold-formed steel structural studs and non-structural metal framing are both frequently used building materials, but they have distinct differences. In this post, we’re focusing on non-structural metal framing, including the key advantages and considerations that may help lower the cost of your next project.

The Differences Between Non-Structural Metal Framing and Cold-Formed Steel

The Advantages of Non-Structural Metal Framing

How to Read Printed Code

Important Non-Structural Metal Framing Considerations

Technical Guides & Resources

FAQs

The Differences Between Non-Structural Metal Framing and Cold-Formed Steel

First, let’s explore the differences between these popular construction materials.

Cold-formed steel refers to thin steel that has been rolled to less than 1/8th of an inch and bent into a specific shape without being reheated. It is often found in appliances, cars, and laptops. Cold-formed steel framing, on the other hand, is used in construction, where thin sheets of steel are typically formed into shapes to take advantage of the material’s significant strength-to-weight ratio.

Cold-formed steel is a very light material to work with. It is also non-combustible, meaning it will not ignite or burn, which helps with a building’s fire rating and safety.

Non-structural metal framing, also known as drywall framing, is thinner and not as robust as structural cold-formed steel. It’s only used for interior studs and cannot be used on load bearing walls. As a standard, it has a thinner galvanized coating that protects against corrosion. For example, a 33-mil interior stud has a lighter coating than a 33-mil structural stud (unless specified otherwise).

These types of studs are not designed for axial loads.

The Advantages of Non-Structural Metal Framing

Non-structural metal framing is lighter, which means it’s less expensive than cold-formed steel. Since it’s also thinner, it’s easier to work with and cut. What does this mean for your project? If you can use non-structural metal framing for interior, non-load bearing walls, your project will be more cost-effective.

Non-structural metal framing has also been tested for composite design (with drywall full-height on both faces). This can result in taller allowable spans. If you can take advantage of these test values, you may be able to build higher with smaller studs.

How to Stud Sizes on the Printed Code

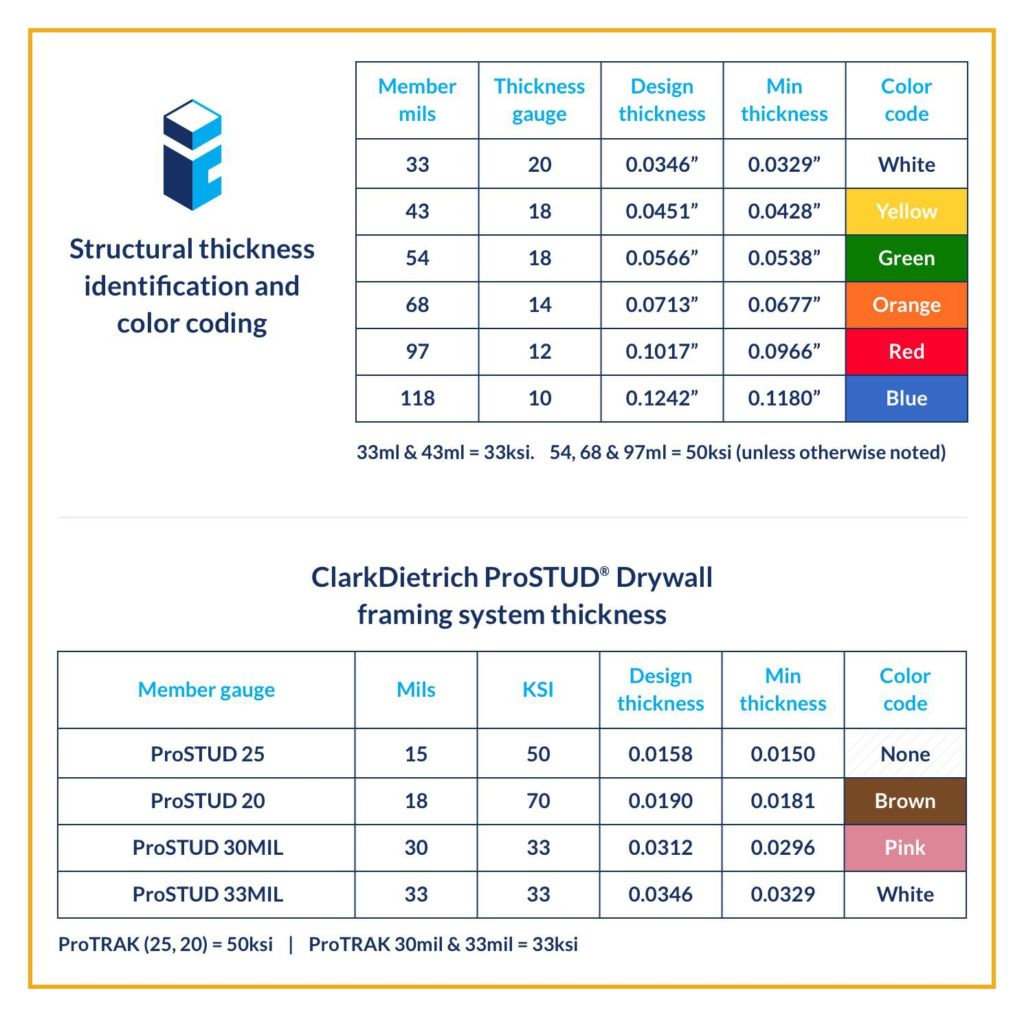

If you’re looking for an easy way to determine a stud’s size just by looking at it, keep this in mind — metal stud manufacturers are required to print the gauge and stud size on every product. Sometimes, however, the code may be difficult to read, and in those cases, colored paint markings will help.

Here’s an example of how to read printed code: ClarkDietrich labels its 6-inch, 16-gauge studs with CD600S162-54 50 KSI. This means the stud is 6 inches with a 1-⅝ inch (1.62 inch) flange and is 16-ga (54 mils) thick. The final number means that the steel strength is 50 ksi. Most non-structural studs are more of a proprietary product, so the material nomenclature might change slightly.

For example, Clark Dietrich’s 3-⅝-inch ProStud, 20-gauge studs will read 362PDS125-18 70 KSI. This means the stud is 3-⅝ inches with a 1-¼ inch (1.25) flange and is 18-mils thick. You’ll notice that these interior studs are made with a much higher strength steel, 70 KSI. These material choices vary widely between manufacturers.

If the code isn’t legible, you can refer to the paint markings.

Important Non-Structural Metal Framing Considerations

One of the most important aspects of using non-structural metal framing is access — in other words, how the studs will actually get into the building. This isn’t a problem when it comes to exterior framing since you’re working on the building’s exterior and can do so from the outside.

When it comes to non-structural metal framing, you may need to coordinate the delivery of the wall studs before the exterior walls are closed in — or ensure that there is another point of access.

In tall wall applications, you may still have to apply bridging, but it can often be avoided if there is drywall applied to both faces of the stud for the full height. You also want to consider detailing door jambs and frames.

It’s important to know when to downsize the thickness of wall studs. For example, rather than designing a stud to span 20 feet, one might consider bracing it at 15-feet with a kicker and/or strongback. This can greatly reduce the cost of framing on certain project. At the end of the day, however, it comes back to the preference of the contractor.

Technical Guides & Resources

Are you looking for codes, standards, and more industry information? We’ve compiled a list of non-structural metal framing technical guides and resources, which include:

The American Iron and Steel Institute (AISI)

The Cold-Formed Steel Engineers Institute (CFSEI)

The Steel Framing Industry Association (SFIA)

ClarkDietrich Building Systems Structural Stud Lookup

ClarkDietrich Building Systems Structural Studs

Product Technical Guide from the Steel Stud Manufacturers Association

FAQs

What’s the difference between a structural and non-structural metal stud?

A structural stud is meant to resist environmental loads (dead, live, wind, snow, or earthquake). They usually have wider flanges and thicker galvanizing. Non-structural studs or ‘interior’ studs are meant for non-load bearing demising walls with gypsum sheathing. These studs typically have flanges that are 1-¼” wide and have a dimpled surface texture. They often have less galvanizing than structural studs and are usually very thin, 33-mil or less.

What is the standard length for a metal stud or track?

Most studs are cut to length that is requested by a supply yard or a customer. Many drywallers order studs cut to the exact length required at the job site to avoid waste and additional cutting. Tracks, however, are stocked standard at 10-feet. Custom lengths are available, but that is less common and may require a longer lead time and possibly a surcharge. It will depend upon the manufacturer and the quantity ordered.

How can I determine the size of a stud if the printed code isn’t legible and the colored paint markings aren’t visible?

Use a micrometer to measure the thickness of the stud — specifically a C-shaped outside micrometer. You can use an inside micrometer, but taking reliable measurements may be difficult with the rounded, sheared edges of cold-formed steel. We recommend taking multiple measurements just to ensure you have accurately determined the stud’s thickness.

Your Trusted Structural Engineering Firm

Here at Iron Engineering, we work with all metal stud manufacturers and have the expert knowledge and experience you’re looking for. If you have questions about non-structural metal framing, or you’re looking for a quote, please contact us today. We look forward to answering your questions and learning about your project.